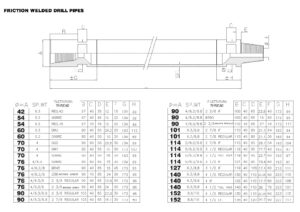

The friction welded drill pipes manufactured by F.G.S. DRILL are made with high quality materials that respond to the mechanical characteristics of yield strength, tensile strength and elongation necessary for the drilling of water wells and for civil engineering.

YS min = 552 N / mm2; UTS min = 690 N / mm2; E min = 14%

The drill pipes are manufactured using the material purchased directly from the best European steel mills, thus ensuring constant quality over time. Production is carried out entirely in the new Bari-Modugno plant using the latest generation of lathes and machinery.

The tool joints are machined from hardened and tempered 42CrMo4 steel and are treated to prevent galling during make up. The hardness of these tool joints is in the range of 43-48 HRC. The threads are checked with certified gauges before being frictioned to the tube.

The rods are available in different lengths up to 7800mm